DS906: The DipScatter Device for Controlling Fires

David Noel

<davidn@aoi.com.au>

Ben Franklin Centre for Theoretical Research

PO Box 27, Subiaco, WA 6008, Australia.

Innovative methods of combatting fires

Unintended fires occurring in buildings and the wider landscape have been the source of major catastrophes since the earliest times.

Fig. DS906-F1. California Wildfires. From [1].

The most wide-ranging fires have been those occurring in forest and bushland -- some of these have spread over thousands of hectares and burnt for long periods, even years. These bush-fires can cause enormous economic loss and sometimes loss of life, and are particular devastating in mediterranean or warm-temperate areas of the world, including much of western and southern Australia and the western United States.

The areas where country and urban activities have their interface contain some of our most valuable agricultural and horticultural industries, and increasingly house those of the population who have moved out of the cities in search of semi-rural living. Not only these high-input industries, but also the infrastructure needed to support them, can be of risk from wildfires.

A 2017 news article [1] said: The death toll continues to rise because of the California wildfires currently scorching across wine country. With 23 dead and hundreds missing, the fires are labeled as a "serious critical catastrophic event", complete with power grid failures.

Fires in cities and towns

Fires in cities and towns are also the source of loss of life and structures. In his book At Home: A Short History of Private Life [6], Bill Bryson mentions that many cities have burned down repeatedly throughout history. This applies both to older cities, where the structures were mainly of timber, and to modern cities, where often the contents of buildings are easily set alight.

The Emperor Nero, of course, traditionally "fiddled while Rome burned". The "Great Fire of London" was a major conflagration that swept through the central parts of the English city of London in 1666, only a year after it had suffered the "Great Plague". Incredibly, the recorded death toll was only 6 people.

Tokyo in Japan was much less fortunate in its 1923 fire. The city was both levelled by a massive earthquake, and ravaged by a fire that swept through the rubble afterwards, resulting in a staggering death toll that some estimates place as high as 142,000 [2]. The single greatest loss of life occurred when approximately 38,000 people packed into an open space in downtown Tokyo were incinerated by a firestorm-induced fire whirl.

What made this disaster so unique was how it combined a number of factors together to produce an especially devastating effect: for example, the earthquake struck at lunchtime when many people were cooking, resulting in numerous fires breaking out throughout the city which then spread rapidly as a result of the high winds from a nearby typhoon off the coast, some of which developed into firestorms which swept across the city.

Fig. DS906-F2. 1923 Great Fire of Tokyo. From [2].

Further, the quake created a tsunami which added to the death toll and the destruction, resulting in the destruction of 570,000 homes and leaving a staggering 1.9 million homeless, giving the day much of a doomsday sort of feel.

The need for more fire-control research

With the scale of such devastation possible, it is perhaps surprising that in modern times, the level of research and experimentation in dealing with unwanted fires has been so minimal. It is true that many regulations are in place to minimize the occurrence of fires, but for many people, the clanging of fire engines going by to attack a fire is still a common occurrence.

There have been changes and advances over the years, but mostly in the means of delivery of water to quench fires. In areas prone to bushfires, such as California and southern Australia, dropping of water from aircraft has become common. Special helitankers have been developed; in Western Australia they are routinely hired in during the bushfire season.

Fig. DS906-F3. Elvis the Erickson Air-Crane helitanker bombs farmland around Narre Warren North, Victoria, in 2009. From [5].

The above picture is from a YouTube video [5] showing a helitanker loading water from a pond and delivering it to the site of a bushfire.

Fires in buildings continue to occur in cities, and these pose dangers to the human firefighters who risk their lives on each fire call they respond to. During those fires, firefighters can encounter explosions, smoke inhalation, burns and the collapsing of burning buildings [3].

Fig. DS906-F4. Fire-fighting robots. From [3].

In China, firefighters are given special robots to extinguish fires [3]. The robots are still controlled by firefighters, and the risks of injuries are little to none.

Methods of fighting fires -- use of Snow

In 2011 a small private LinkedIn group, the "FRIG: Fire Research Innovation Group", was set up to look at innovative approaches to fire control. The now-defunct Zombal facility was used to find investigators for some novel or little-known approaches here.

One of the first of the ideas looked at was using snow to fight fires. Commercial snow-making machines can be bought off the shelf, they are used by ski-run operators and snow-sports competitions when natural site conditions do not produce enough snow for the events.

Don Moloney produced an excellent report [7] on using snow as a fire-fighting agent, which not only examined the particular medium, but also gave a good insight into the basic factors operating in effective fire control.

Moloney found that snow could be an ideal fire-fighting product. Here is an extract from his report.

The delivery of high velocity snow may be an ideal fire fighting product for the following reasons:

* High rate of flame penetration, targets and cools fuel source directly.

* Low temperature aids cooling of fuel.

* High surface area aids rapid heat transfer significantly and makes better use of the same volume of water.

* Low temperature further aids in rapid heat transfer.

* Additional energy requirement to raise temperature of snow through phase change solid-to-liquid as well as liquid-to-gas.

* Depending on the use of air or inert gas, may displace oxygen, choking the combustion process.

* As snow evaporates, steam further displaces oxygen.

It was surprising to find just how effective snow could be as a fire suppressant, when considered using the principles of modern fire fighting. The high surface area and large energy required to vaporise snow make it ideal for rapidly cooling gases, extinguishing fire, displacing oxygen, cooling boundaries and preventing re-flash.

Unfortunately for the snow idea, the energy requirements to produce snow at the site of a fire proved prohibitive. The very factors which made snow such a good fire-control agent (by sucking energy out of a fire), meant that that a great deal of energy would be needed at the fire site to produce the snow from water. Not least of these was that the water had to be cooled considerably to make the snow. Moloney says [7]:

These power requirements are fairly prohibitive. For example if we wanted to half-match our 240 LPM fire hose for water output, we'd require a 1600 kW plant just to produce the ice. This is enough to power approximately 1000 homes, or 2-and-a-bit Formula-1 racing engines at full power, or one and a half M1 Abrams battle tanks.

This doesn't mean it's impossible. A GE T700 gas turbine engine costs $328,000, outputs 1200kW and is designed to fit in a helicopter. That shaft power could produce, potentially, 3kg of ice per second, which is comparable to our typical fire hose output. Similarly, Detroit Diesel 1000kW generator sets can be found for under $100,000 and are designed to be towed by truck. Engines in this range burn between $500 and $1500 of fuel per hour.

Methods of fighting fires -- use of Carbon Dioxide

Carbon Dioxide (CO2) is a familiar material for use in fire-fighting, it is the material used in many of the hand fire-extinguishers found in buildings and vehicles. Many municipal fire codes require such fire-extinguishers to be available at sites accessed by the public. We can call the output stream from such fire-extinguishers "CO2 Mist".

Fig. DS906-F5. CO2 Mist from a carbon-dioxide fire extinguisher. From [4].

Carbon Dioxide is a very interesting substance. At ordinary atmospheric pressures, it has no liquid state. CO2 can be frozen, to form solid carbon dioxide or "Dry Ice", and blocks of this are often used to keep drinks or other foodstuffs or materials cool. When dry ice is exposed at room temperatures, its surface does not melt, but changes directly to vapour (the process is called sublimation), without a liquid phase.

However, if CO2 (as vapour) is held under a little over 5 atmospheres pressure and cooled, it will condense into a liquid. The pressure needed is not extreme, it is about 70 psi, around that in a bicycle inner-tube.

According to Wikipedia [8], carbon dioxide has no liquid state at pressures below 5.1 standard atmospheres (520 kPa). At 1 atmosphere (near mean sea level pressure), the gas deposits directly to a solid at temperatures below -78.5 deg. C and the solid sublimes directly to a gas above -78.5 deg. C. In its solid state, carbon dioxide is commonly called dry ice.

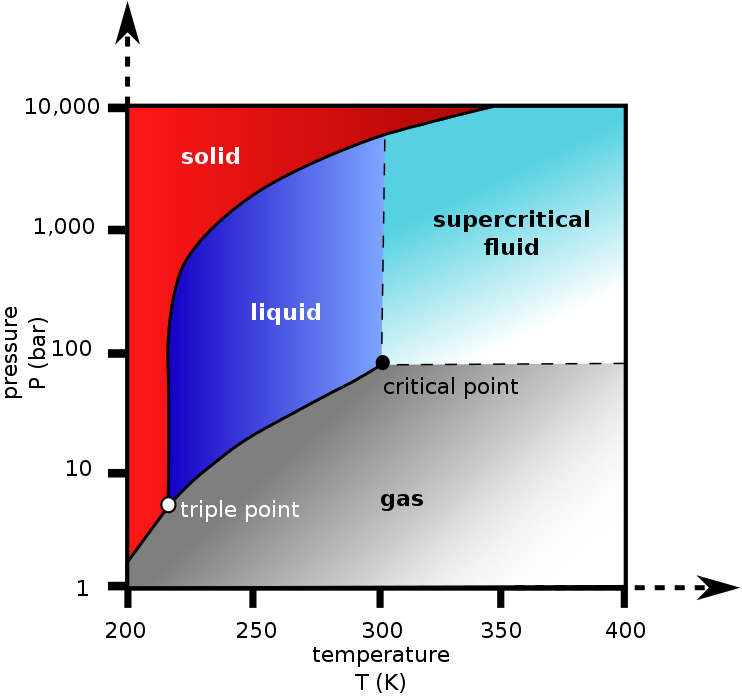

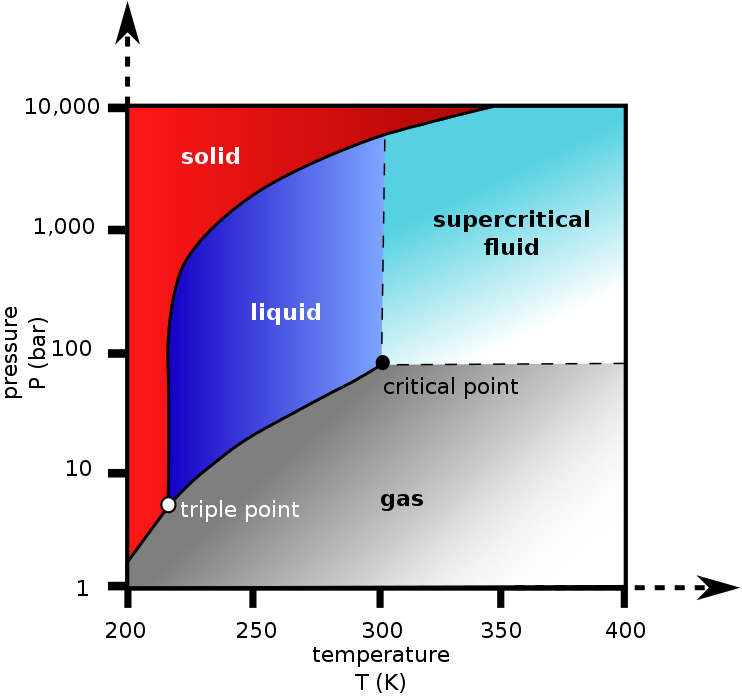

For those interested in the scientific background of CO2, its various phases are affected by temperature and pressure, and it can exist as vapour (gas), solid, and liquid, and also as what's called a supercritical fluid -- neither liquid nor gas. In the following diagram, the vertical scale is in Bars (atmospheres) and the horizontal scale in degrees Kelvin (300 K is 27 deg C, room temperature).

Fig. DS906-F6. Carbon-dioxide phase diagram. From [8].

The carbon dioxide in CO2 fire-extinguishers is held in the form of a liquid under pressure. When the nozzle is released, the CO2 changes to vapour and expands greatly, gushing out. The CO2 also cools naturally by the expansion process, making it better to cool a fire.

Methods of fighting fires -- use of Dry Ice Pellets (DipScatter)

Another innovative possibility for fighting fires is the use of Dry Ice Pellets -- solid carbon dioxide pellets. These appear to have almost all the virtues of snow, without its drawbacks.

In 2011 another request was placed on Zombal specifically to examine the the use of DIP (Dry Ice Pellets) for fire control. It was as follows.

"Wanted, a sketch design for delivery of dry ice pellets from an aircraft or balloon. Dry-ice pellets are commercially available in a range of sizes (eg 3 mm, 6 mm, 12 mm) or can be easily made in situ from liquid carbon dioxide. A sketch design for a system to deliver a stream of pellets from an aircraft onto fires is wanted.

Because dry ice is colder (-78 deg C) than ice, and needs more energy (1.7 times) to change from solid form than ice, it should be very effective at sucking energy out of fire zones. Evaporating carbon dioxide makes a heavy mist which should also aid in fire suppression".

There were no responders to this request. But, from what has already been said, the use of Dry Ice Pellets was clearly a promising method of fighting fires (DipScatter). Carbon dioxide is proven for fire suppression, and bringing it to a fire in a solid, easily handled form, and in as large quantities as needed, seems a great idea.

The virtues of snow for fighting fires have been explained above, what kills its practical use is the need for applying large amounts of energy at the site. With carbon dioxide in solid or liquid form, the need to apply energy at the fire site is eliminated.

About Dry Ice Pellets

Dry-ice pellets are a commercial product which can be bought at retail and wholesale from manufacturers in larger cities. They are widely used in food industries and other enterprises which need to keep items cool. You can front up at a supply point with your esky (insulated container), and buy pellets by the kilogram for your picnic or fishing trip.

Fig. DS906-F7. Dry ice pellets. From [11].

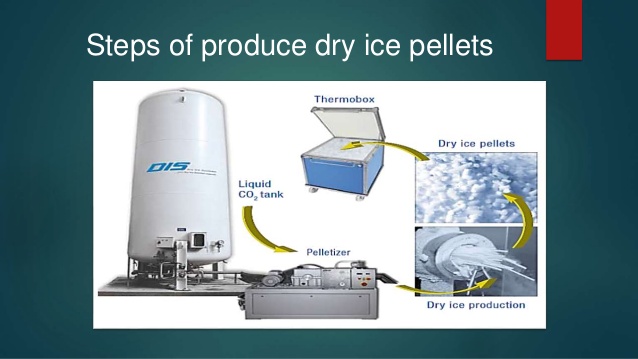

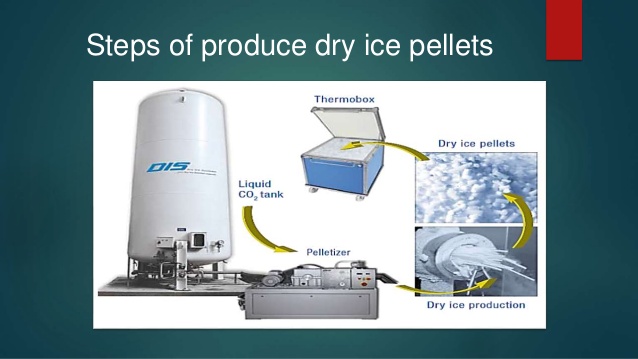

Pellets are commonly 5 mm in diameter and cost maybe $7-10 per kilo. The manufacturer makes them from liquid carbon dioxide using a pelletizer, which forms solid CO2 and extrudes it through circular holes of the required diameter in the pelletizer output disc.

CO2 is produced as a by-product in various manufacturing processes, including brewing, and will normally be purified to food grade if it will be used to make pellets for public sale. The bubbles in carbonated drinks are CO2, and dry-ice pellets can be added to bulk drink containers to make the drinks fizzy.

Fig. DS906-F8. The dry-ice pellet production process. From [10].

Pelletizers vary in size and technique, but typically are about the size of a refrigerator and are used in a fixed position, though they could be vehicle-mounted. There is a brief YouTube video at [12] showing dry-ice pelletization.

Fig. DS906-F9. Pelletizer making dry-ice pellets. From [12].

Using Dry-Ice pellets for cleaning

Dry-ice pellets can be used in an innovative process to clean surfaces easily, in place, and without contamination from solvents, liquids, or sand particles. According to [9], dry ice blasting uses small pellets of dry ice sprayed through a jet nozzle with compressed air to remove paints, oil, grease, dirt, ink, adhesives and other materials you want to remove. The frigid temperature of the dry ice against the dirty surface causes adhesion to shrink and loosen from the surface. On immediate impact, the dry ice evaporates into environmentally safe and innocuous CO2 gas.

Fig. DS906-F10. Dry-ice pellet blasting machine. From [9].

In [13] it says "This method is superior to sandblasting because the dry ice is soft enough not to pit or damage the underlying surface. The dry ice sublimes quickly into the air and only the removed material must be cleaned up.

Dry-ice blasting eliminates equipment damage in two ways. Dry ice does not erode or wear away the targeted surface as traditional grit media (and even wire brushes) do, so surface integrity and critical tolerances are preserved and equipment will not have to be replaced due to surface erosion. Second, with traditional cleaning methods, equipment is often damaged while in transit to or from a dedicated cleaning area. With dry-ice blasting, most equipment and machinery can be cleaned in place".

Fig. DS906-F11. Dry-ice pellet blasting equipment in use. From [14].

DipScatter Machine trials

In Perth, Gordon Hall runs a dry-ice pellet cleaning business called Subzero Dry Ice Blasting. Gordon was kind enough to demonstrate the use of a blasting gun at his workshop, and to participate in a live fire-fighting trial at a fire training centre in Perth.

This trial was very kindly facilitated at the Falck organization's IFAP Fire Training Site by Neil Hackett, the Training Centre Manager. Prepared dry-ice pellets were kindly supplied by Stuart Mayne of BOC Gases, and Stuart was also able to supply useful information on CO2 applications, and to show me a pelletizer machine.

The trial used one of Gordon's pellet blasting guns and compressor, which we can call DipScatter Machine Mark 1. This was used to fire CO2 pellets at a drum fire at the training centre. In another simple trial, a shovel was used to dump some CO2 pellets on the fire.

The Mark 1 trial showed that the CO2 pellets were effective at suppressing a fire, but that the throughput of a cleaning gun was insufficient to permanently dampen a fire. In the cleaning technique, the emphasis is on accelerating the pellets to a high speed with a minimum use of material, to achieve effective cleaning. The pellet stream was able to extinguish a small timber fire, but the fire was liable to re-ignite from glowing embers.

DipScatter Machine Mark 2

To achieve a higher throughput of pellets, a different approach was needed. A household vacuum cleaner would provide a good airflow which could carry pellets, but the airflow passes through a filter which would stop solids. A domestic lawn vacuum, intended to pick up leaves from a lawn or driveway and collect them in a bag, seemed to be a possible basis for DipScatter Machine Mark 2.

A discarded lawn vacuum was picked up from a council bring-out-your-rubbish verge collection in Subiaco, together with a couple of old vacuum-cleaner hoses. These were assembled into the Mark 2 prototype as shown.

Fig. DS906-F12 The Mark 2 DipScatter prototype.

The unmodified electrically-driven lawn vacuum (blue and black parts in the photo) consisted of a collection hood (to pick up leaves), a fan motor, and a bag to collect the leaves (this was suspended from the handle, as in an upright household vacuum cleaner).

Fig. DS906-F13. Detail of the Mark 2 prototype.

To adapt this to make the Mark 2, the bag was removed and replaced with plastic piping (white parts in photo) which directed the air flow to the front. A flexible hose and nozzle was fixed to the plastic piping, so that the expected pellet flow could be directed as desired.

The inlet mouth of the collection hood was sealed off, and a second hose was attached to the top of the hood, to serve as the airflow inlet of the device. On starting the fan motor, air was sucked in through the inlet hose and expelled through the outlet hose. If the inlet hose nozzle was placed into some loose material such as sand or sawdust, the material was sucked through as expected.

A trial was arranged at Gordon Hall's workshop to test the prototype with dry ice pellets -- no fire was involved, it was expected that pellets would be sucked in from an insulated container and expelled onto the workshop floor. This trial was successful, with a good throughput of pellets, but with an unexpected feature.

Fig. DS906-F14. Flow of CO2 through the Mark 2 prototype.

The unexpected feature was the Mark 2 converted most of the pellets to CO2 mist. This was not necessarily a drawback, the substantial flow of CO2 mist should be excellent for initially damping a fire -- compare the flow to that from a CO2 fire extinguisher, as in Figure F5 above.

A 48-second video clip of the operation of the Mark 2 can be seen on YouTube [15], just click HERE to watch it. At the end of the clip, non-sublimated CO2 pellets can be seen on the floor of the workshop. It appears that contact of pellets with the fan blades was converting most of them to CO2 mist.

In my view, this clip provides ample Proof-Of-Concept for the idea of using dry-ice pellets in firefighting.

DipScatter Machine Mark 3

Following the successful trial of the Mark 2 DipScatter machine, work was begun to modify this to allow it to vary the proportion of dry-ice pellets which would be converted to CO2 mist. This version, the Mark 3, is as shown in the illustration.

Fig. DS906-F15. The Mark 3 prototype.

In this version, an insulated box was added as a hopper to hold pellets. Under the box, a plastic pipe and gate valve (as used in home irrigation systems) was added, which led into the outlet nozzle of the machine. The intention of the design is that, with the gate valve closed and the inlet hose open to the air, switching on the machine would deliver just a stream of air at the outlet nozzle.

If the inlet hose was then inserted into the esky box containing pellets, the machine should deliver a stream of mostly CO2 mist at the outlet. If the inlet hose was free in the air, and the gate valve opened, the machine should deliver a stream of non-sublimated pellets, with the extent of flow controlled by opening or closing the gate valve.

It seems very possible that if such a DipScatter machine was used to tackle a small fire, the best approach would be to smother the fire with CO2 mist, and then dampen it completely with a layer of pellets. In a more advanced layout for the machine, pellets could be fed into the airstream from the hopper either before the fan (creating CO2 mist), after the fan (leaving them as pellets), or a combination of both. The simple Mark 3 prototype would have provided a way for testing the concept without more engineering.

In the event, it did not work out to have a trial of the Mark 3 with an actual fire. Nevertheless, I believe that the DipScatter Machine concept is well worth pursuing both for its social utility and commercial possibilities.

Anyone with the interest and capability of doing this, is urged to do so. I am not seeking to be involved, but am willing to help if asked.

Commercial development of the DipScatter Machine

A commercial developer will make their own decisions on how to proceed, but I think the best approach might be to develop and sell (or hire out) small DipScatter machines to businesses, workshops, offices and the like as the next step up from hand fire-extinguishers.

These might be in the form of DipScatter Cabinets, locker-size units holding one machine and one or more insulated hoppers holding dry-ice pellets. The cabinet would plug into mains electricity, used to refrigerate the dry-ice hoppers or pods and to maintain the machine's battery at full charge.

In use, the machine would run on its slotted-in lithium ion battery, as in the modern cordless electric lawn mower shown.

Fig. DS906-F16. Battery-powered lawnmower. From [16].

This machine runs for about an hour on one battery charge, depending on conditions of use, ample for the time which might be needed to tackle an in-house fire. The mower shown sells for under $250, so a production-model DipScatter Machine should be feasible for a similar price.

A member of staff in an office or workshop should be able to operate such a machine with very minimum training -- training is not currently expected to operate a hand fire-extinguisher. Special clothing is not necessary (in Figure F11, the operator is working in shirt-sleeves), and even if a machine was operated poorly, no bad consequences would be expected, less than if a water hose was used to tackle a fire.

In the introductory phase, it might be commercially advisable to offer the DipScatter Cabinets for lease, as well as for sale, so that a new client could have DipScatter Cabinets fitted without much capital outlay. Even with refrigeration and very good insulation, some loss of pellet material must be expected over longer periods, so CO2 pellet pods would need checking and topping up perhaps once a year.

Larger-scale uses of CO2 for fire-fighting

The DipScatter machine as discussed would be suitable for tackling small fires by untrained persons in the vicinity. Clearly the principles involved could easily be adjusted for larger fires, perhaps involving professional fire personnel.

For intermediate-scale fires, or for first attack on fires, tonnages of pre-prepared pellets could be brought in and applied. This setup avoids the main drawback of using snow for firefighting, in that pellet application would not need a major power source at the fire scene.

For even larger fires, tankers containing liquid CO2 could be brought in to the fire scene and converted simply to pellets at the point of application. While commercial pellet production focuses on minimum loss of CO2 to CO2 Mist during controlled production, rapid conversion to pellets, as in Figure F9, makes a pellet/mist combination which should be ideal for fire-fighting.

In a possible building-protection approach, liquid CO2 could be piped throughout a large retail or residential building, as the equivalent of modern water sprinkler systems, automatically triggered on detecting a fire. CO2 sprinklers would be much less destructive than water sprinklers on the building contents, as the CO2 just evaporates.

All these approaches could be adapted for tackling bush fires and forest fires, including supply of CO2 by aircraft, unmanned balloons, and helicopters as in Figure F3. While more costly than using water, CO2 might be much more effective in initial dampening and control of a wildfire.

Enter the WireBots and RhinoBots

There is much scope in professional firefighting for the use of robots and automatic equipment, as in the Chinese robots shown in Figure F4. Here we can pick out a couple of scenarios, each could be extended to fit varying circumstances.

The WireBot. The WireBot would be a roughly humanoid figure, able to climb stairs and open doors, with some degree of autonomy but connected to a human operator through trailing vision and power cables. It would also trail a liquid-CO2 hose.

With a fire in an apartment block, the WireBot would be able to enter through a door and proceed to the flame point, spraying CO2 as necessary as it proceeded. Persons and objects could be picked up and extracted from the building, without risk to the operator.

The RhinoBot.

The RhinoBot would be a much larger and more autonomous vehicle, able to tackle wildfires and extensive factory fires, with some degree of radio supervision. It would carry its own tonnage of liquid or pellet CO2, and use a vehicle flywheel as its propulsive and energy source, thus avoiding dangers associated with carrying inflammable fuel.

In Switzerland, flywheel-powered "gyrobuses" have been able to travel up to 10 km on one charge (spin-up) of their flywheel. For details of this and related devices, see DS903: The KPW (Kilogram Power Wheel) [17].

Other development approaches to firefighting

Another approach to firefighting which looks to have good promise is the use of fine water mists. Water mists actually use up very little water, and are effective because the high-surface-area droplets are very efficient at absorbing heat energy.

Although not widely known or appreciated, some work has been done in this area. In Don Moloney's report [7], it has this to say.

For example, commercial water-mist fire fighting systems expel water at extremely high pressures (of up to 100 atmospheres of pressure or more) which creates a very fine mist of water droplets (each droplet smaller than 0.15 mm).

The high surface area to volume ratio of these tiny droplets mean they absorb heat and evaporate at a much faster rate than conventional sprinkler systems. This results in a high rate of energy absorption and hence highly effective fire control.

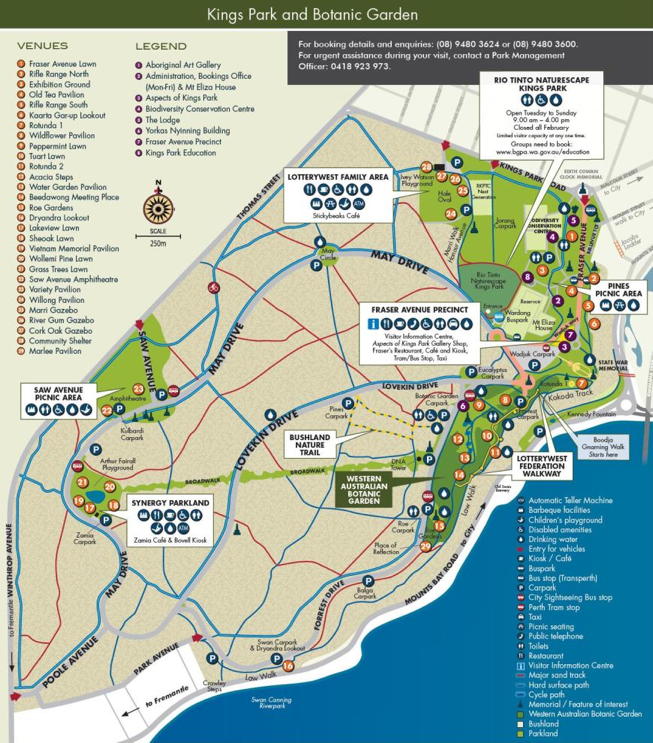

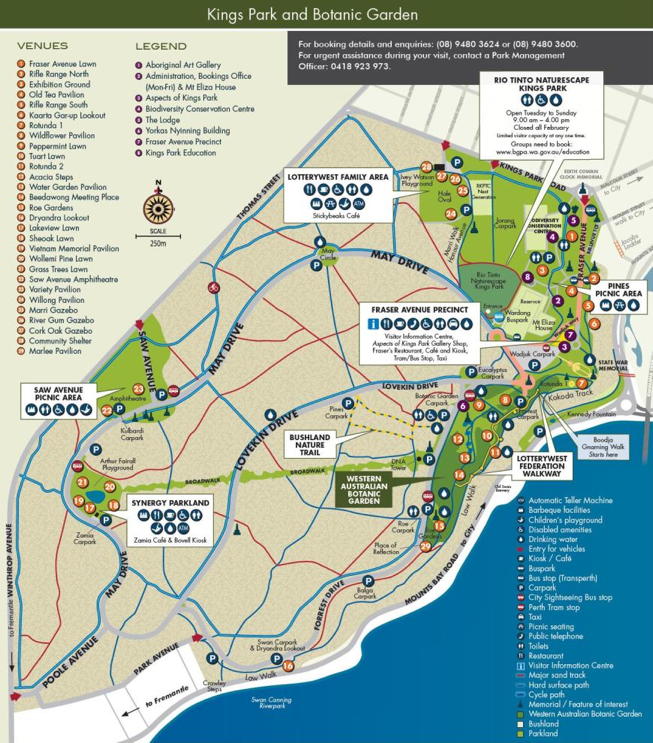

An area where such systems might be particularly useful is in urban and near-urban sites containing natural bush. In Western Australia, with many areas prone to bush-fires, the capital Perth contains a large central park, Kings Park, much of which is still natural bush.

Fig. DS906-F17. Kings Park. The light brown areas are mostly natural bush. From [18].

Every few years, an outbreak of fire occurs somewhere within Kings Park -- some fires are believed deliberately lit by firebugs.

Fig. DS906-F18. Within Kings Park, showing extensive bush-vegetation areas. From [19].

For highly-valued sites such as Kings Park, it seems reasonable to install water-misting nodes fed from mains water supplies. These could set themselves off automatically on detecting a fire. Periodic maintenance testing, or setting off such systems as a precaution in anticipation of dangerous conditions, would do no harm to the bush itself or to animals or people present.

* * * * * * * * * * * * * * * * * *

References and Links

[1]. Mac Slavo. Power Grid Failures: CA Wildfires Are Now A Serious Critical Catastrophic Event. http://www.thefringenews.com/power-grid-failures-ca-wildfires-are-now-a-serious-critical-catastrophic-event/ .

[2]. Top 10 Most Famous Fires in History. http://www.toptenz.net/top-10-most-famous-fires-in-history.php .

[3]. Watching Chinese Robots Battle A Massive Fire Shows What The Future May Hold For Fire Fighting. https://www.virascoop.com/watching-chinese-robots-battle-a-massive-fire-shows-what-the-future-may-hold-for-fire-fighting/ .

[4]. Carbon dioxide fire extinguisher discharge time. https://www.youtube.com/watch?v=uV1j4xFvAoQ .

[5]. Elvis water bombing Narre Warren North. (video) https://www.youtube.com/watch?v=P3SjRZtnIIg .

[6]. Bill Bryson. At Home: A Short History of Private Life. Doubleday, 2010..

[7]. Don Moloney. Snow as a fire-fighting agent. http://assets.zombal.com/e763151d/Snow%20as%20a%20fireWN.pdf .

[8]. Carbon dioxide. https://en.wikipedia.org/wiki/Carbon_dioxide .

[9]. Dry Ice Blast Cleaning Machines. http://www.finishingmachines.com/dryiceblasting.htm .

[10]. Mohamed Kandil. Dry ice project. https://www.slideshare.net/MohamedKandil5/dry-ice-project .

[11]. Dry Ice Pellets. http://www.lidcombeice.com.au/dry-ice-pellets.html .

[12]. Making Dry Ice Pellets. https://www.youtube.com/watch?v=EXEnuFU9N8g .

[13]. Dry Ice Blasting Principles. http://www.coldsweep.com/dry-ice-blasting/ .

[14]. Dry Ice Blasting. http://www.getreallist.com/u-s-grid-power-storage-charges-up.html .

[15]. DipScatter Machine Mark2 -- Applying pellets of dry ice (solid carbon dioxide) for fire-fighting. Delivery trial. https://www.youtube.com/watch?v=AX6BEY0YE4I .

[16]. Giantz Lawn Mower Cordless Lawnmower Lithium Battery Powered Electric Garden. https://www.amazon.com.au/Giantz-Cordless-Lawnmower-Lithium-Electric/dp/B07788TDDC .

[17]. DS903: The KPW (Kilogram Power Wheel): A domestic power storage device replacing batteries. http://www.aoi.com.au/devices/KPW/ .

[18]. Venues and Facilities. https://www.bgpa.wa.gov.au/kings-park/visit/maps-and-transport/venues .

[19]. The view west from the DNA Tower. http://www.spiritland.net/kings_park.htm .

Go to the Devices Home Page

Version 1.0 compilation started 2018 Mar 17, on Web 2018 Apr 24.